Innovating in square one | Lumios Materials has a different approach to carbon fiber production

Learn how Lumios Materials' Founder, Evan Stacy is addressing bottlenecks in carbon fiber production and making it more accessible for various applications.

When Evan Stacy was knee-deep in his Ph.D. program at the University of Southern Mississippi, a side project evolved into tackling one of the biggest bottlenecks in carbon fiber production. Today, he’s commercializing that technology through the Innovation Crossroads program at Oak Ridge National Laboratory (ORNL).

Innovating in Square One

When carbon fiber is produced, step one of the process is turning liquid material into a solid. Most carbon fiber today starts with a synthetic polymer called “polyacrylonitrile (PAN).” Then, it undergoes extrusion and a spinning process to solidify the material.

Stacy explained that many people are familiar with carbon fiber, yet it has not been widely adopted for use. Why?

“It’s expensive to make. You can point to a number of different places in the production stream that contribute to that cost, but we’re focused on the initial step where you take a liquid material and use a catalyst to make it solid,” he said.

That’s the big bottleneck of the carbon fiber industry, he shared.

“If you have a really strong reason to innovate in square one of the production process, you have to do it,” he said. “That’s why we’re committed to changing the method.”

Stacy’s company is called “Lumios Materials,” named after the Greek word for “light.”

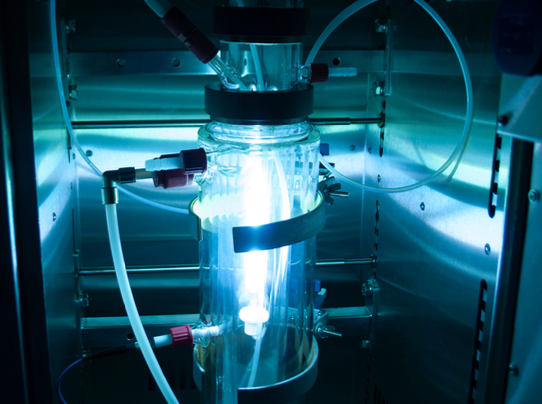

The name is symbolic of Stacy’s innovative process, which uses LED light to catalyze liquid polymers.

His team is harnessing light to reimagine carbon fiber production through a process called PRISM: photo-regulated innovation of structural materials.

“It is going to make carbon fiber better, faster, and cheaper on the market,” he said.

Stacy sees a wide application for this process, affecting industries across the United States and globally; however, his first areas of focus are aerospace and automotive. Both of these industries have a strong need for cost-effective carbon fibers.

The road to East Tennessee

While discovering, developing, and testing this technology on a small scale at the University of Southern Mississippi, the opportunity just grew and grew and grew!

“Suddenly, we got too big for USM in that we didn’t have the right equipment to actually take the next leap, and that’s where we got connected with Oak Ridge National Lab,” Stacy said. “We became aware of a program called Innovation Crossroads, saw that it had the resources to take our innovation to the next level, applied, and got accepted into the program.”

It was the catalyst for relocating himself and the newly created company to East Tennessee.

“It’s been an exciting and candid journey. Two years ago, when I started this work, I had no intention of being an entrepreneur. I didn’t think I had what it takes. I didn’t think I had the technology for it. That’s why this whole thing is so special – it has been such a natural innovation pathway,” he said.

In the first three months of the Innovation Crossroads program, while awaiting his Cooperative Research and Development Agreement (CREDA) with the U.S. Department of Energy (DOE) and ORNL to be approved, Stacy participated in the Spark Cleantech Accelerator at the UT Research Park at Cherokee Farm.

He said the program lived up to its name.

“My first five-minute pitch was packed with highly technical data. If you weren’t a trained polymer scientist, you’d have no idea what I’m talking about,” he said. “After Spark, I feel very poised, for we’re ready to take on VC funding. I know what investors are interested in. And, I know what I need to be doing before even getting to that game.”

We will keep you up to date on Lumios Materials developments.

Like what you've read?

Forward to a friend!