TreisD begins manufacturing operations for anti-counterfeiting technology in Knox County

The 3D imaging startup relocated its headquarters and manufacturing to the Knoxville region, citing world-class talent, university partnerships, and a welcoming entrepreneurial community.

Counterfeit goods cost consumers a fortune, and most buyers have no idea how deep the deception runs. From apparel and accessories to makeup, alcohol, and even medications, nearly every category of consumer goods has been touched by counterfeiting.

Counterfeit goods are annually a $2 trillion global industry.

The Times reports that as much as 65 percent of cosmetics sold on online marketplaces are fake. And, nearly 30 percent of alcohol consumed worldwide is estimated to be illicit, resulting in an annual loss of around $8.9 billion in fiscal revenue.

Counterfeiters have adapted quickly, designing products that fool even the savviest shoppers. That leaves a critical question: How can well-known brands protect both their products and their reputations?

John Brandon, the Chief Executive Officer of TreisD Corporation, believes the answer lies in the packaging.

“Big Pharma has a problem. Supplements have a problem. Cosmetics have a problem,” Brandon said. “We want to come alongside those brands to help them make more secure packaging.”

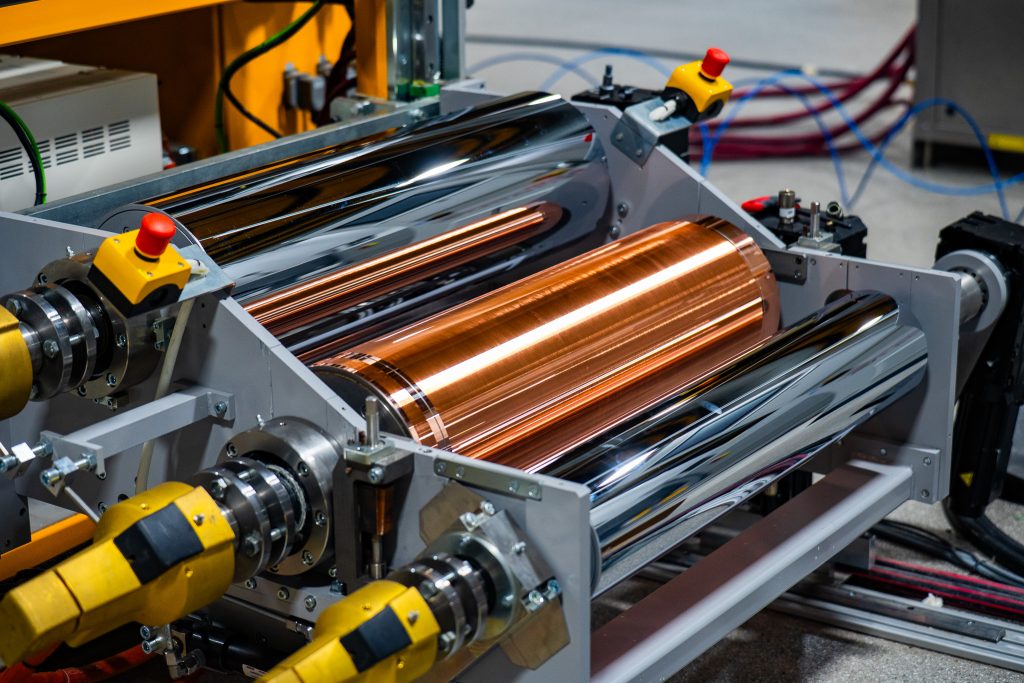

TreisD accomplishes this through a patented process for 3D printing on product packaging, and the company will produce its materials at a new facility in Mascot, Tennessee.

New to the Neighborhood

TreisD is new to the neighborhood. The company announced its anticipated relocation to East Tennessee in July 2025.

Teknovation.biz interviewed Brandon about TreisD’s proprietary technology, its new production operations in Mascot, and the reasons behind the company’s decision to move to Tennessee.

“There were some reasons that we began to consider moving and placing our manufacturing operations,” Brandon said. “Because of a long-time relationship that I had with Governor Bill Haslam, I called Governor Haslam and said, ‘Does it make sense for us to consider moving this startup to Tennessee?’ And of course, his answer was yes.”

The team evaluated potential sites in Nashville, Chattanooga, and Knoxville before selecting Knoxville for its headquarters at the UT Research Park at Cherokee Farm and Mascot for manufacturing.

“It became clear to us that the best place for us was Knoxville,” Brandon said.

He outlined three main factors. First, the company wanted access to strong technical talent. The University of Tennessee, Knoxville (UTK), graduates thousands of students each year across engineering and materials sciences. Second, TreisD recognized UTK’s polymer science department at the Institute for Advanced Materials and Manufacturing as one of the best in the world. And finally, Brandon said the hospitality they encountered in Knoxville was unmatched by any other city they toured.

One of the most impactful introductions was to Three Roots Capital and its president and CEO, Grady Vanderhoofven, along with director of lending, Dennis Corley.

“Three Roots Capital has been a fantastic partner for us. When we first came to Knoxville, they were one of our early introductions,” Brandon said.

Three Roots led TreisD’s debt syndicate to build the custom manufacturing equipment needed for its extrusion line. The organization later invested in TreisD as well.

“They are the unique partner that has helped us on the debt side and on the equity side,” Brandon said.

Vanderhoofven said the relationship has been mutually beneficial.

“I think one of the most compelling things about TreisD is the people,” he said. “They have the experience, a track record, and they know what they are doing. They have a very clear understanding of the market and the capability to build the technology.”

How does the technology work?

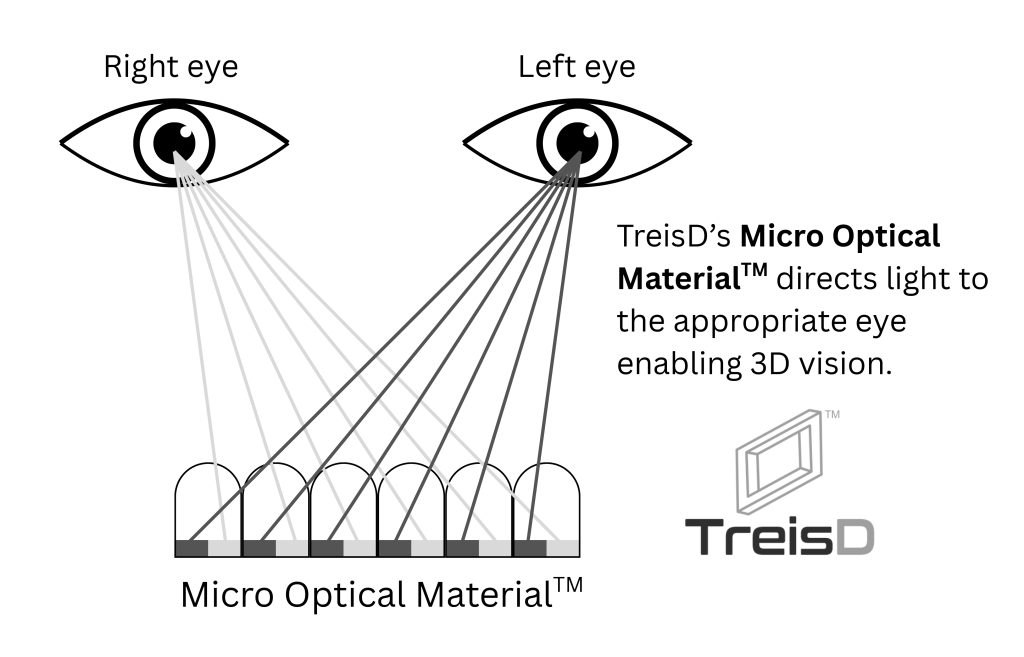

TreisD, as its name suggests, specializes in 3D imaging. The company transforms 2D visual elements into digital 3D images that match the way the human eye perceives depth.

Those images are then printed onto a film that cannot be replicated.

TreisD founder Dr. Jerry Nims has worked in 3D visuals for decades. He invented the well-known Nimslo 3D camera in the 1980s in Japan.

The Nimslo captures multiple images at once, creating a moving 3D effect without the need for glasses or a headset. It allows users to produce images that mirror the human visual system. That innovation ultimately laid the foundation for the technology TreisD uses today.

“Dr. Nims decided a few years ago to take all the things that he learned in the analog world and move them into the digital world,” Brandon said.

Today, that digital technology is active inside TreisD’s new Mascot facility, where the startup built an extrusion line to manufacture a thin, specialized polymer film that can support 3D imaging.

“We are delighted to be in East Tennessee. I am a Silicon Valley guy, so I did not really know what to expect bringing a startup to Knoxville,” Brandon said. “But I feel like it is a hidden gem when it comes to creating an environment where startups are going to flourish.”

Like what you've read?

Forward to a friend!